This website uses cookies in order to offer you a more personalized navigation experience. For more information about the cookies we use, please see the strictly necessary cookies, third party cookies and additional cookies sections on the left menu.

What you need to know about the most suitable storage systems for the food sector

Changes in consumer buying habits are forcing food sector companies to continually reassess their distribution networks and models. And now more than ever, since the lockdown situation due to the Coronavirus made food sales increase exponentially compared to in a normal period. Not only did physical sales from supermarkets and online sales increase, demand also varied enormously for certain items. This unexpected growth also brought about a collapse of the logistics.

Food sector growth is now more moderate, but it still doubles the levels registered before the COVID-19 crisis. Therefore, rapid demand forecasting and an optimised logistics network are crucial factors in this sector.

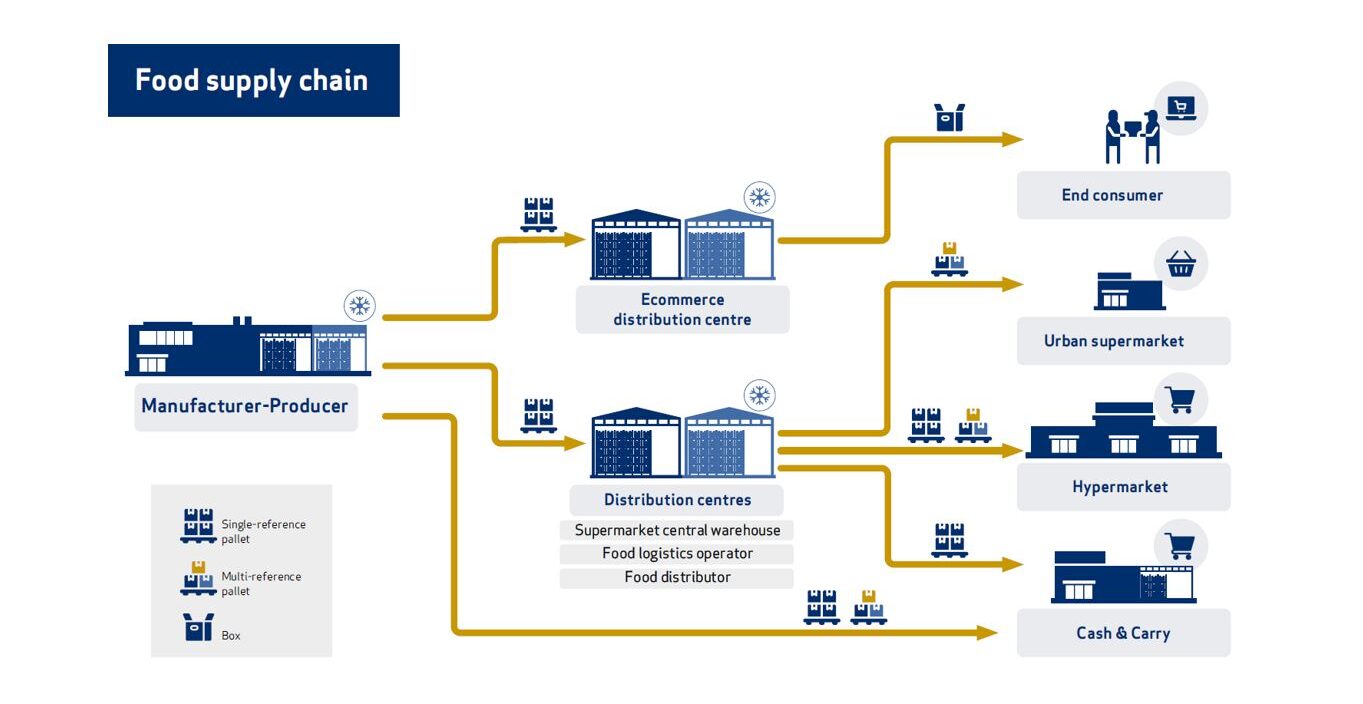

Food sector supply chain

Optimum functioning of the whole of the supply chain guarantees that each product will arrive at the end consumer on time and preserving all hygiene and freshness guarantees.

In the food sector, there are 3 types of warehouses based on the temperature at which the products need to be stored:

- Dry goods or room-temperature warehouse

- Refrigerated warehouse, with stores between 3 and 12 °C.

- Freezer warehouse, with stores at -30 °C.

For refrigerated or frozen products, it is essential not to break the cold chain at any point. During the chain of storage with the producer, at the distribution centre, in the actual supermarket, and during transport from one location to another, we must guarantee that the products are stored and transported at the corresponding temperature. To achieve this, it is important to know about the most appropriate storage methods and systems.

Storage systems for the food sector

Food companies’ goods are palletised throughout the entire supply chain path, except in the case of online purchases, where the orders are prepared in crates or small cartons delivered directly to the end consumer.

In the case of supermarkets, hypermarkets, and cash&carry outlets, the same pallet that leaves the producer’s facility reaches the supermarket without being handled, even if it has passed through the warehouse of a food logistics operator or distribution centre.

However, in urban supermarkets, the goods that arrive from the producer have been previously taken off one pallet and placed on another with a consolidated order for the store. Because the volume of products required is not the same as for a supermarket or a hypermarket.

In the food sector, which works with goods that are perishable or have a short shelf life, it is crucial for storage solutions to maintain an adequate stock rotation. Also, based on the type of product to be stored, a FIFO or LIFO goods management method will be chosen.

These are the most commonly used storage systems in the food industry:

- Drive-In: this is a compact system of storage in blocks that provides maximum compacting, ideal for storing large volumes of goods with few references. This type of system is common in the warehouses of finished goods manufacturers.

- Shuttle: this is a compact system similar to the drive-in but semi-automated. This solution handles the loads using a shuttle, which helps to save time in product handling.

- Pallet live storage: this gravity-based system is configured in FIFO mode to guarantee that the first pallet in the shelf will be the first one out.

Distribution centres from which the goods are supplied to stores require a picking area to be able to prepare pallets with consolidated orders or boxes/containers for direct delivery to the consumer. This picking area will be made up of manual live storage or racking for manual loads with shelves.

In the case of refrigerated stores, space optimisation is even more important. The less the space required for storage, the less the space required to be refrigerated. This helps to reduce the energy cost required for constant maintenance of the store’s refrigeration.

To store products in cold storage facilities, we can choose the among following solutions:

Conventional pallet racking on mobile platforms: one single corridor provides access to all pallets stored and this way optimises the space available to a maximum.

Automated warehouse: operated automatically by robotised equipment that handles the loads, avoiding warehouse operator exposure to low temperatures, additionally optimising the space a lot better.

Mezzanine or raised walkways: in the order preparation area, instead of using the dry storage bay, we can instal raised walkways or mezzanines to make the most of the refrigerated store’s height space.

Why is proper supply chain management so important?

It avoids financial losses generated through incorrect storage and handling of the goods. Such as expired or obsolete products.

Helping to generate customer loyalty. Thanks to warehouse management efficiency, we will guarantee on-time delivery in optimum conditions, thereby improving customer care. If the experience is satisfactory, they are more likely to repeat.

Improved returns. Optimising the storage space reduces land costs and avoids unnecessary movements of personnel.

The situation generated by the COVID-19 pandemic has demonstrated that consumer habits can change at any time. New habits can arise naturally or for reasons of force majeure as occurred with the pandemic. At the same time, it is important for the food sector to have the most flexible possible warehouse management and logistics distribution network dynamically adaptable to changes that can arise. Improvising in such a situation is not advisable, so it is important to rely on a specialised supplier in storage system design, production, and installation.

At POLYPAL we design warehouses for the food sector by studying current requirements and future forecasts. We configure your warehouse to be as dynamically adaptable as possible to improve your capacity to respond to situations that require quick adaptation due to unexpected changes in demand.