Warehouse layout: correct layout design and its benefits

The warehouse layout is the design or distribution of the warehouse on plan, as a step prior to the project’s execution. Therefore, it is the most important phase when it comes to acquiring and starting to manage a warehouse. Its design must be aligned with the company’s objectives and contribute to their achievement, in addition to covering the company’s current and future needs.

A layout design can be motivated by 3 situations: change of location requiring a redistribution of the existing warehouse in a new building; modification of the existing warehouse, or opening of a new warehouse starting from scratch.

However, irrespective of the motive, layout design must meet the following objectives:

- Optimise the available space to a maximum.

- Reduce the number of movements, distances, and time spent on load handling.

- Facilitate access to the merchandise.

- Facilitate stock control.

- Be flexible if a change is required in the distribution of the stored goods.

Benefits of preparing an adequate layout

- Improved returns. By optimising the storage space, use of the available space is maximised, reducing land costs

- Improving warehouse safety: as we optimise the flow of materials, congested areas are eliminated avoiding unnecessary operator movements.

- Avoiding financial losses generated through incorrect storage of the goods.

- Helping to generate customer loyalty. Thanks to warehouse management efficiency, guaranteeing on-time delivery in optimum conditions. This improves customer care and increases their satisfaction.

What factors must we consider in designing the warehouse layout?

Merchandise:

We need to know the characteristics of the goods to be stored. From the type of load unit, to its dimensions and minimum and maximum weights. We also need to consider if the goods require storage at a specific temperature: room temperature, refrigerated or frozen. Details such as the number of references, etc., will also help us to design the layout.

Regarding storage of the products, several aspects must be considered:

Products must be correctly packaged to guarantee they are protected from dust, moisture, or damage they could sustain during handling.

We will try to store goods that have special requirements on account of their nature, such as liquids, flammable materials, fragile products, etc., in separate zones distinct from the rest of the goods, such as in ATEX (Explosive Atmosphere) zones.

Warehouse characteristics:

The warehouse dimensions will determine the building’s storage capacity, layout of the goods inside it, and design of the racking system.

In most cases, warehouse design begins as part of an existing infrastructure but it could be that the warehouse structure has yet to be built. In this case, we have more freedom to configure our layout, and can even choose to build a clad-rack or self-supporting warehouse, where the racking constitutes the main structure of the building.

In designing the warehouse, we will not only make maximum use of the available surface, we will also maximise use of the space at height whenever possible.

Good flows and rotation in the warehouse:

Knowing the movements performed for incoming and outgoing goods from the warehouse will condition the design of the layout. Movements of goods in the warehouse imply costs and time, therefore, we will try to minimise them insofar as possible.

It is also important to know about product rotation. Products with a higher rotation will be placed in easy access zones for location and handling.

Storage systems in-keeping with our requirements:

Before choosing the ideal storage solution, we must identify the particularities of the product to be stored:

– Product rotation

– Storage capacity we wish to achieve

– Stock volumes

– Load unit: big bags, pallets, crates, loose or bulk products…

– Number of references we work with

– Are the products perishable

– Do the products require storage at a controlled temperature

– Type of handling equipment we work with.

Handling equipment:

We must analyse the type of handling equipment suitable for our storage system and the number of units required for an efficient operation, bearing in mind the number of warehouse operators if this handling equipment is to be manually operated.

Human resources:

Knowing the number of operators who work in the warehouse, their shifts and organisation will also help to design a more optimised storage facility.

What are the main zones to be considered in designing a warehouse layout?

Although the warehouse layout will depend on numerous factors, both physical, inherent to the actual warehouse, and organisational, when it comes to preparing the floor plan, they must all have identified perfectly delimited zones.

Therefore, layout design will consider the following warehouse areas:

Loading and unloading zone:

Enough space must be available for unhindered access by transport vehicles.

Reception zone:

This zone will be situated as close as possible to the unloading area. Here, the quality controls take place, the goods are sorted and if necessary, their packaging is replaced for appropriate storage. Therefore, in this zone of the warehouse we will need to consider the following areas.

- Quality control area

- Sorting area

- Adaptation area

Storage zone:

This is where the products will be deposited and kept in storage. To correctly locate the stored references, we will consider the following areas in this zone:

- Low rotation area

- High rotation area

- Special products area

- Goods picking and collection area

Order preparation zone:

This is the place in the warehouse where the order is picked and prepared. It can be integrated in the storage zone, or be in a separate zone exclusively dedicated to this operation.

The order preparation zone is not necessary in all warehouses. It will only be planned in cases where the outgoing merchandise has a different configuration to the incoming merchandise. For example, goods that arrive on pallets and depart in boxes.

Dispatch zone:

Once the order has been prepared, this zone performs grouping of the goods to be dispatched, packages them and prepares them for loading onto the means of transport for delivery.

The layout of this warehouse zone will consider:

- Load consolidation area

- Packaging area

- Dispatch control area

Auxiliary zones:

The layout, in addition to the inherent zones dedicated to storage and handling of the goods, must also consider the auxiliary zones needed for optimum operation of the warehouse:

- Returns area

- Packaging or containers area

- Obsolete materials area

- Office or administrative area

- Charging zone for handling equipment

- Changing rooms and toilets area

Types of layout

To design the layout of a warehouse we need to know about all of the movements and operations performed with the goods inside it.

We can consider 3 types of operating flows:

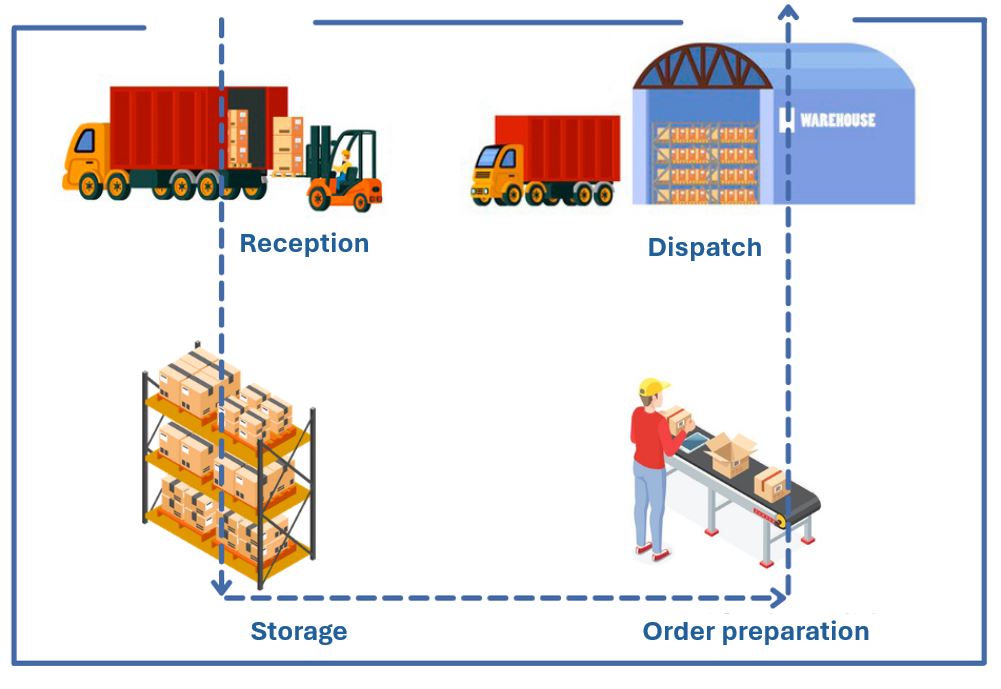

U-shaped flow

Reception and dispatch of the goods are performed from the same bay and in the same direction. The goods enter through one side of the building, are stored, then move to the order preparation area, and exit through the bay situated next to the entrance bay.

A U-shaped layout makes vehicle loading and unloading flexible and facilitates future extensions or modifications of the warehouse.

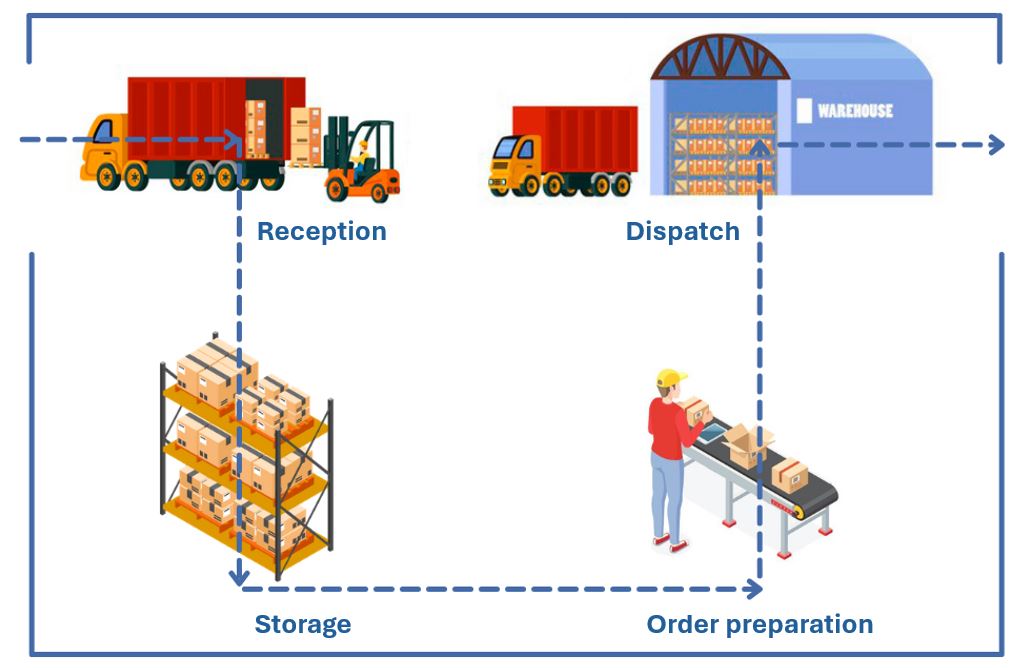

T-shaped flow

In this variation of the U-shaped flow, goods enter and leave from separate bays situated facing opposite each other. In this case, because the bays are separate they can be used independently.

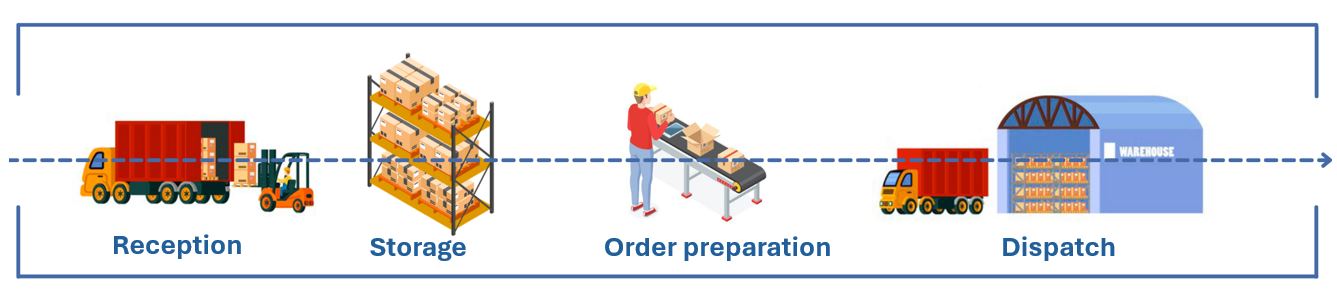

Linear flow

Here the loading and unloading zones are situated in zones away from each other and the system is not as flexible as in the case of U or T-flows. The goods follow their path without returning through the central part of the warehouse. This flow is less flexible as there is no immediate access to the goods arrival and departure points.

Correctly designing the layout will help you to optimise the space, reduce storage costs, increase safety, and improve the service offered to your clients.

At POLYPAL we work with our clients to guide them in the preparation of their warehouse layout and design of the storage solution best suited their needs.

Tailor-made solution

If you are not sure which storage solution best suits your needs, please contact us. We will help you get your project off the ground.