The pallet live storage systems of POLYPAL are compact structures where roller lanes with a predefined inclination are used to shift the pallets downwards by means of their own weight.

They can be designed for FIFO operation (first in / first out, first pallet to enter first pallet to exit) or LIFO (last in / first out, first to enter last to exit). Both systems guarantee a fast and organized flow of the pallets, but each one has its particular characteristics:

FIFO

In FIFO Dynamic racks, the pallets are loaded into the gravity lanes on the entry side, where the slope causes them to move at a slow and controlled speed. , from the loading point to the unloading point. When a pallet is unloaded, the next pallet occupies its space and is ready for its removal.

Available volume is optimized by requiring only one loading aisle and one unloading aisle, against other rack systems that require additional aisles. The differentiation of loading and unloading aisles results in high-performance handling of the goods.

The dynamic FIFO racking from POLYPAL is the best solution for the storage of perishable products that require a perfect stock rotation.

LIFO

In the LIFO Dynamic Racks, the loading and unloading of the different lanes is made at the front of the block from the same aisle.

After placing the first pallet on the lanes, to store the second pallet the operator pushes the first along the rollers with the second load, and then the first and second with the third and consecutively until the lane is full. Unloading is made inversely, the first pallet loaded is the last one removed from the lane.

In this system, the number of pallets stored is prioritized, as only one aisle is required thus freeing space for more storage or other duties.

Features

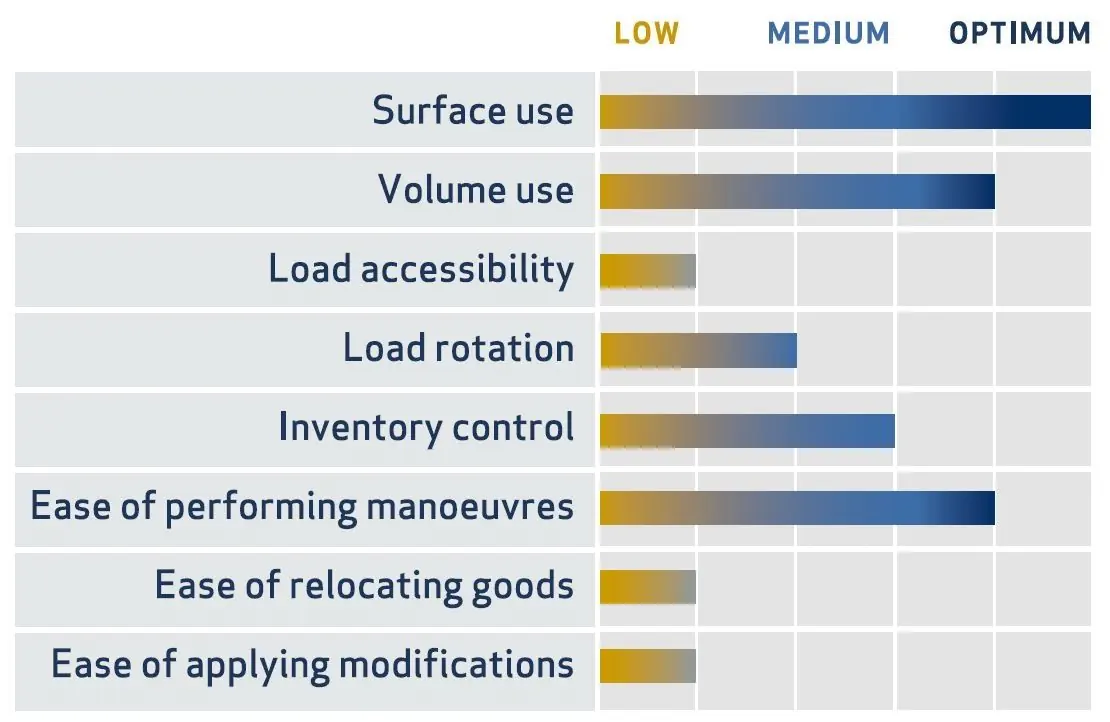

Characteristics of the pallet live storage:

- As a compact system, the load capacity is maximum.

- Allows a perfect rotation of goods without needing additional stock control systems.

- Low maintenance and without energy consumption.

- Low operating costs, you need less task force and less forklifts.

Are you interested in any of our products?

Request a quote

Racking Safety Inspections

POLYPAL has a Racking Safety Inspections Service for warehouses with pallet racking.